KULITE PRESSURE TRANSDUCERS DISTINCTIVELY DIFFERENT

The sensors used in all modern Kulite pressure transducers are dielectrically isolated, silicon-on-insulator (SOI) devices. This is the fundamental distinction between a Kulite sensor and those employed by most other manufacturers of silicon pressure transducers. Kulite sensors consist of a complex structure of three layers atomically bonded together.

The first layer is of monocrystalline N-type silicon. This layer is micromachined into a mechanical pressure sensitive diaphragm. The thickness of the diaphragm varies with the full-scale pressure range for which it is intended. The thickness is chosen so that this layer will see approximately 350 to 400 micro-inches per inch strain at that full-scale pressure. This is a very conservative level of strain for mono-crystalline silicon, ensuring long-lasting robust mechanical sensor operation.

The second layer, which is of silicon dioxide, is grown right on top of the N-type silicon diaphragm. This layer provides dielectric isolation between the N-type silicon and the P-type silicon of the layer containing the Wheatstone bridge circuit, thus eliminating P-N junctions from the design of the device and enabling higher temperature operational capabilities.

The third layer is fusion bonded to the layer of silicon dioxide, at the intermolecular level, through a proprietary, high-temperature process. This layer contains four strain gages of P-type silicon patterned in a Wheatstone bridge circuit. Patterning of the P-type silicon is done using photolithography and Reactive Ion Enhanced (RIE) plasma etching to ensure precise dimensional control of the strain gages. The strain gage network, including interconnections, comprises one continuous integrated circuit of P-type silicon The individual elements of this circuit are isolated from one another by a layer of silicon dioxide, which is a continuation of the layer of silicon dioxide separating the layer of N-type silicon from the layer of P-type silicon.

The physical relationship between the locations of the strain gage elements of this third layer and the mechanical diaphragm of the first layer are such that when pressure is applied, the resulting strain in the diaphragm causes two of the strain gages to go into tension (thereby increasing their resistance) and two of the strain gages to go into compression (thereby decreasing their resistance). The two gages in tension are opposite each other in the Wheatstone bridge schematic. Similarly, the two gages in compression are opposite each other in the bridge, such that the applied stress causes a resistance imbalance maximizing the output of the bridge. The magnitude of this imbalance is directly proportional to the magnitude of the stress applied. This is the fundamental operating principle behind all “strain gage” pressure transducers. For the advantages of the Kulite approach to this concept, visit the section of this site titled Sensor Benefits.

KULITE LEADLESS TECHNOLOGY

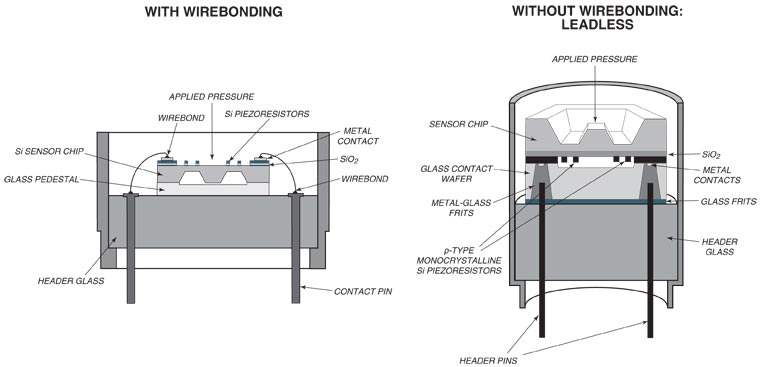

Historically, the interconnection between the silicon sensor and the rest of the transducer circuit has been accomplished via fine gold wires. The wires are welded to metal contact pads on the sensor and then to a pin or a printed circuit board elsewhere in the transducer. These wires and their welds are susceptible to failure due to fatigue under conditions of high vibration or rapid pressure cycling. This approach is still employed by other manufacturers of silicon pressure transducers.

In the “leadless” pressure transducer, these fine gold wires – and all the problems associated with them – have been eliminated. The sensor is bonded to a glass layer to form a hermetically sealed, solid mechanical structure. Gold pins embedded directly in the package insert into the glass with a conductive paste facilitating electrical connection between the pins and sensor chip. The sensor structure is secured and hermetically sealed to the package using specialized materials and techniques to form a sealed, mechanically robust structure comprising the package and sensor chip. Conventional electrical connection is made directly to the back of this sensor-header structure, which can be installed in a wide variety of sensor housings. This allows it to be adapted to a wide variety of applications. Even ultra-miniature pressure transducers based on this technology can be used with any fluid, including conductive fluids, as long as they are not hostile to silicon or glass. They can be used to temperatures as high as 932°F (500°C). For a more detailed description of this technology and its benefits, please visit the section of this site titled Reference Library.